NSF Early Career Development (CAREER) Program awards are highly prestigious, offered to early-career faculty members who demonstrate the potential to serve as academic role models in research and education.

Three ME faculty members have received this prestigious award in 2022. Congratulations to all three recipients!

|

|

|

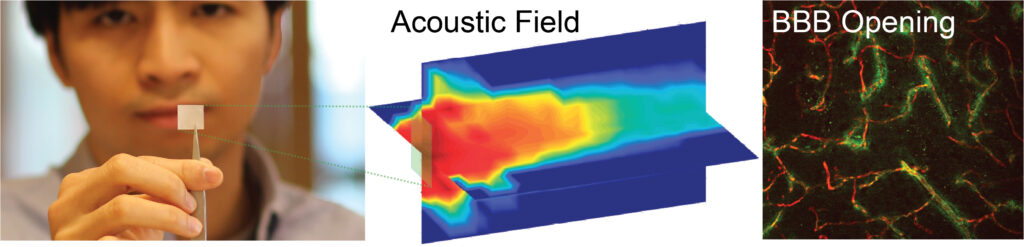

| Hongyi Xu | Anna Tarakanova | George Matheou |

Prof. Xu’s award will support his group’s research on design of mixed stochasticity structural systems. The award received by Prof. Tarakanova will support fundamental research to understand complex changes to elastin that occur in aging and disease. Prof. Matheou’s grant will focus on large scale computational models of low could transitions in the atmosphere to support a better understanding of their impact on climate change.

With these three awards, the total number of NSF CAREER or DoD Young Investigator Awards won by ME faculty since 1996 increases to 25 with seven of these awards having been received in the last three years!

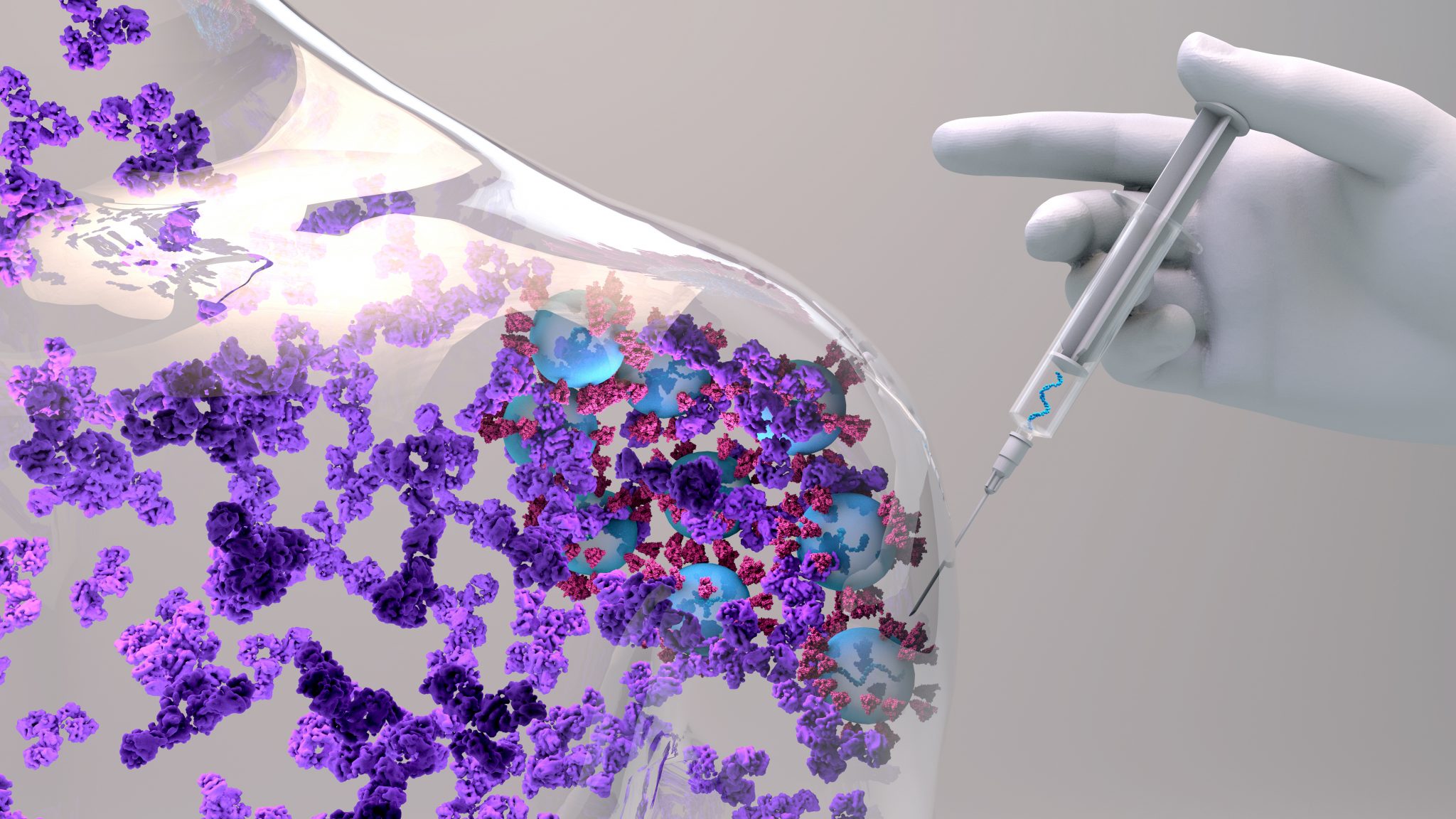

Prof. Julian Norato has received a new ARPA-E grant to study Topology Optimization and Additive Manufacturing for Performance Enhancement of High Temperature and High Pressure Heat Exchangers.

Prof. Julian Norato has received a new ARPA-E grant to study Topology Optimization and Additive Manufacturing for Performance Enhancement of High Temperature and High Pressure Heat Exchangers.