by Olivia Drake

In a paper published as an Editor’s Pick in Applied Physics Letters, College of Engineering’s Georges Pavlidis outlines ways to manage heat in high-speed electronic.

When electronic devices overheat, they can slow down, malfunction, or stop working altogether. This heat is mainly caused by energy lost as electrons move through a material—similar to friction in a moving machine.

Most devices today use silicon (Si) as their semiconductor material. However, engineers are increasingly turning to alternatives like gallium nitride (GaN) for longer lifetime use and higher performance. This includes products such as LEDs, compact laptop chargers, and 5G phone networks. For even more extreme applications—such as high-voltage systems or harsh environments—researchers are exploring ultrawide bandgap (UWBG) materials like gallium oxide (Ga2O3), aluminum gallium nitride (AlGaN), and even diamond.

The key difference between these materials lies in their electronic bandgap—the energy needed to get electrons to flow through the material. Wider bandgaps allow companies to reduce the size of their electronics and make them more electrically efficient.

“UWBG materials can resist up to 8,000 volts and can operate at temperatures over 200 °C (392°F), making them promising for the next generation of electronics in the energy, health, and communication sectors,” explains Georges Pavlidis, assistant professor of mechanical engineering.

While these materials offer promising advantages, they also come with challenges. They’re currently expensive, difficult to manufacture, and their thermal behavior is hard to measure precisely. As electronics become more powerful and in smaller dimensions, the heating in the device becomes more localized and can generate a heat flux greater than the sun, Pavlidis explains.

“Chip manufacturers need new methods to measure temperature in smaller dimensions,” he says.

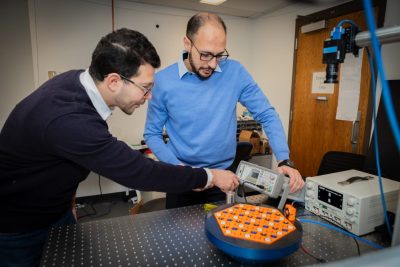

Pavlidis, along with UConn’s School of Mechanical, Aerospace, and Manufacturing Engineering Ph.D. candidates Dominic Myren and Francis Vásquez, collaborated with colleagues from the U.S. Naval Research Laboratory over the past year to tackle the challenge of measuring the heat output. Their work resulted in a “Perspectives” paper published in Applied Physics Letters.

Anna Tarakanova

Anna Tarakanova

Professor Jiong Tang, a distinguished figure in the field of mechanical engineering, has recently been honored with the prestigious ASME Myklestad Award in 2024. This award, established by the American Society of Mechanical Engineers (ASME), recognizes individuals who have made significant contributions to vibration engineering, particularly in areas related to analytical methods, experimental approaches, and practical applications in mechanical and aerospace systems. Prof. Tang’s work exemplifies the high standards of innovation, rigor, and impact that the Myklestad Award celebrates, showcasing his commitment to advancing the field of vibration engineering through both fundamental research and practical advancements.

Professor Jiong Tang, a distinguished figure in the field of mechanical engineering, has recently been honored with the prestigious ASME Myklestad Award in 2024. This award, established by the American Society of Mechanical Engineers (ASME), recognizes individuals who have made significant contributions to vibration engineering, particularly in areas related to analytical methods, experimental approaches, and practical applications in mechanical and aerospace systems. Prof. Tang’s work exemplifies the high standards of innovation, rigor, and impact that the Myklestad Award celebrates, showcasing his commitment to advancing the field of vibration engineering through both fundamental research and practical advancements.