Prof. Xu Chen is the recipient of the UTC Institute for Advanced Systems Engineering’s Breakthrough Award, which recognizes innovative, transformational and disruptive contributions in the field of advanced systems engineering. Read more here.

News

From Realistic Human-Computer Interaction to Nanomachines: Prof. Horea Ilies has recently received 3 grants form the National Science Foundation totaling $1.35M

Three recent grants have been awarded by the National Science Foundation to Prof. Horea Ilies to support the current research in his Computational Design Laboratory.

The ability to measure how well objects “fit together” is a key task in engineering design and manufacturing as well as in the broad scientific arena whenever the behavior and function of a system is dependent on proper geometric alignment. For example, assembly planning from macro to nanoscale, layout optimization and packaging, design for human variability, synthesis and self-assembly of nano-machines, novel drug design, comparative shape analysis (shape similarity), as well as personalized medicine and medical devices are all applications in which the system’s behavior and function depends on the proper geometric alignment of individual components. One of the grants, based on the work with Dr. Morad Behandish, focuses on developing a generic framework for geometric interfaceability in virtual product development aimed at quantifying and interpreting how well objects of arbitrary geometric complexity fit together.

A second grant is exploring the extension of the geometric interfaceability framework to develop effective  haptic interaction mechanisms for intelligent human-computer or human-robot systems with a focus on virtual assembly tasks. The research uses haptic devices, which add the sense of touch when interacting with digital models and simulations, and are used in a variety of research, industrial and consumer applications, from engineering design, to computer-assisted surgery, and gaming.

haptic interaction mechanisms for intelligent human-computer or human-robot systems with a focus on virtual assembly tasks. The research uses haptic devices, which add the sense of touch when interacting with digital models and simulations, and are used in a variety of research, industrial and consumer applications, from engineering design, to computer-assisted surgery, and gaming.

The latest NSF-grant received by Prof. Ilies, in collaboration with Dean Kazem Kazerounian, focuses on the systematic design, analysis and control of manufacturable nanomachines such as the nanorobots built from protein molecules. In this research, Profs. Ilies and Kazerounian aim to develop a theoretical and computational framework to systematically design, and analyze self-assemblable molecular machines with prescribed mobility and function obtained from a predefined library of molecular primitives. The research aims to develop the tools required to perform design space explorations for synthetic and controllable molecular machines and devices, potentially leading to novel molecular motor functions that can be used to develop smart nanorobots and materials.

A paper authored by Morad Behandish and Prof. Horea Ilies places 2nd in the Best Paper Award Competition at the 2015 SIAM/ACM conference on Geometric and Physical Modeling.

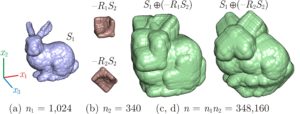

A paper authored by Dr. Morad Behandish and Professor Horea Ilies placed 2nd in the 2015 SIAM/ACM conference on Geometric and Physical Modeling. The conference, with a historically low acceptance rate below 30%, brings together applied mathematicians, computer scientists and engineers from academia and industry to exchange new ideas in relevant mathematical theory, geometric and physical modeling, analysis, simulation and processing, as well as various applications. The title of the paper presented with this award is “Analytic Methods for Geometric Modeling via Spherical Decomposition,” and has been published in the special issue of Computer-Aided Design, vol. 70, pp. 100-115, January 2016.

Previously, the two UConn researchers won two consecutive Best Paper Awards at the 2014 and 2015 Computers and Information in Engineering (CIE), which is part of the annual international ASME IDETC & CIE Conferences.

Prof. Michael T. Pettes receives the NSF CAREER award

Prof. Michael T. Pettes is the recipient of a National Science Foundation CAREER award from the Chemical, Bioengineering, Environmental, and Transport Systems (CBET) NSF Directorate for his proposal “CAREER: Understanding the Roles of Strain and Mass Disorder on Fundamental Thermal Transport Processes in Two-Dimensional Materials.” Read more in the UConn Today article.

Morad Behandish and Prof. Horea Ilies win two consecutive Best Paper Awards at the 2014 and 2015 ASME IDETC & CIE conferences.

Dr. Morad Behandinsh and Professor Horea Ilies won two consecutive Best Paper Awards at the 2014 and 2015 Computers and Information in Engineering (CIE), which is part of the annual international ASME IDETC & CIE Conferences. Their papers, titled “Peg in Hole Revisited: A Generic Force Model for Haptic Assembly,” and “Haptic Assembly Using Skeletal Densities and Fourier Transforms” were selected among the 143 and 130 papers, respectively, presented at the two CIE conferences.

The state-of-the-art in haptic-assisted virtual assembly is based on a distinction between two modes of function, namely, a free motion mode implemented with collision detection engines, and an insertion mode during which the software assists the user in the precision assembly task by providing geometric virtual constraints. The identification of the switch criteria between the two modes has been one of the open problems in virtual assembly of complex objects. The two UConn researchers have developed a novel technique to automatically detect the geometric constraints for assembly guidance using a generic force model that applies to objects of arbitrary shape. They showed that their approach creates the attraction forces and torques towards the assembly configuration corresponding to proper alignment as well as the repulsion forces and torques in case of collisions. Their work, supported by National Science Foundation, is the first one to unify the free motion and insertion modes during virtual assembly into a single functional mode for shapes of arbitrary complexity.

A(n Academic) Family Business

During the 2014 conference, the organizers of the flagship international event on Design Engineering, which is the ASME IDETC & CIE Conference, honored two other awardees that are closely connected to the UConn researchers.

Vadim Shapiro, the Bernard and Frances Weideman Professor of Mechanical Engineering and Computer Science at the University of Wisconsin received the Design Automation award for his outstanding contributions to geometric and physical modeling. Herb Voelcker, the Charles Lake Professor of Mechanical Engineering Emeritus at Cornell University received the CIE Lifetime Achievement Award to “recognize a person who has had a significant impact on the use of computers in engineering practice and/or education.” Shapiro is Ilies’ academic PhD advisor, and Voelcker is his academic grandfather, which makes the 3 different prizes awarded concurrently to this academic family for independently conducted research an extraordinary experience.

Prof. Savas Tasoglu: an inexpensive and portable method of monitoring and predicting sickle cell related strokes.

Prof. Savas Tasoglu is working on an inexpensive and portable method of monitoring and predicting sickle cell related strokes by measuring sickle cell disease with a smart phone.

Lee Langston Receives ASME Sawyer Award

By Kristi Allen

Mechanical Engineering professor emeritus Lee Langston is the 2015 recipient of the R. Tom Sawyer Award presented by the American Society of Mechanical Engineers. The Sawyer award is conferred on an individual “who has made important contributions to the toward the advancement of the gas turbine industry.” Forty-three men from all over the world have received the award, which is a major industry honor.

In his 30 year career at Pratt & Whitney and UConn, Langston pioneered the measurement, understanding and prediction of secondary flow in gas turbines, or jet engines. His research in gas turbine flows is known collectively as the Langston cascade. He has also authored more than 75 scholarly journal articles and holds one patent. “I started working on the problem [of complicated flows in gas turbines] in 1974…All the work is still referred to,” said Langston. The R. Tom Sawyer award is closely tied to the history of the gas turbine engine. The award was named for Robert Thomas Sawyer, an earlier pioneer in the industry who founded the ASME’s International Gas Turbine Institute, which grants the award.

Langston has been involved with the International Gas Turbine Institute since 1974, serving as a member of the board of directors several times and as vice president between 1997 and 2000. The list of Sawyer award recipients includes English engineer Sir Frank Whittle and German physicist Hans von Ohain, the two men credited with independently developing the first jet engines in the late 1930’s. “I’m honored to be included on the list, especially with those two men,” Langston said. The award was presented to Langston this summer at the annual International Gas Turbine Institute conference, TURBO EXPO, held this year in Montreal. Langston earned his bachelor of science in mechanical engineering at UConn in 1959 and his Ph.D. from Stanford in 1964. He returned to Connecticut and worked as a research engineer at Pratt & Whitney from 1964 until 1977 when he joined the UConn engineering faculty as an associate professor.

Langston became a full professor in 1983, served as interim dean of the School of Engineering from 1997 to 1998 and was awarded the title of professor emeritus in 2003. Langston has seen the gas turbine industry transform and grow immensely over the course of his career. The efficiency and reliability of gas turbine engines has allowed both commercial and military aviation to expand to once unimaginable places. “It’s fantastic; aviation is booming,” said Langston. “For some reason, it doesn’t get the same kind of attention that other technologies get.” Gas turbine engines cost about 10 to 20 percent of what the original aviation piston engines cost to maintain and average just one in-flight failure about every 30 years. The engines themselves have improved in efficiency over the years, creating major cost savings for airlines and making air travel affordable for the masses. There are currently almost 20,000 planes in the worldwide air transport fleet, with that number projected to grow 75 percent by 2030 . In 2011, the total aviation gas turbine engine market totalled $32 billion.

Gas turbines engines are also used in a growing number of applications on land, particularly in power plants. Langston helped bring some of this technology to UConn in the form of the co-generation power plant opened in 2006. The plant uses three gas turbine engines to generate power for the campus. They’re more efficient and environmentally-friendly than the original oil-burning engines the plant used because they use cleaner natural gas and harness both electrical energy and steam energy from a single source. “Gas turbine engines reduce CO2 emissions by almost 75 percent when they replace coal-fired power plants,” said Langston. “I was really proud to be a part of updating UConn’s power plant.” In addition to his work as a researcher and professor, Langston has also had a distinguished career as a mountain climber. Two of his most notable climbs include summiting Chimborazo Volcano in Ecuador, the farthest point from Earth’s center, and the first ascent of a peak in Pakistan known as T3 led by legendary climber Willi Unsoeld. When asked what it’s like to stand at the top of a mountain, Langston said “there’s this moment of exhilaration, but then you have to go down…

Most accidents happen on the descent.” Langston said caution has been the key to avoiding disaster during a climb. He spoke about turning around just a few hundred meters from the summit of a volcano in Ecuador which had begun to spew intense sulphuric gases. Langston and his wife continue to travel frequently. He currently writes a quarterly column and an annual review of the gas turbine industry for Mechanical Engineering magazine and serves on the ASME’s Technical Committee on Publications and Communications and the History and Heritage Committee. Langston has spent his career contributing to a field that has revolutionized global transportation and energy production, a field which looks to be no less innovative in the coming decades. He looks forward to watching the growth of the industry in the future. Published: November 18, 2015

2012 D. E. Crow Innovation Prize Winners

2012 D. E. Crow Innovation Prize Winners

Thirteen student teams competed for 20,000 of prize money on May 10, 2013 presenting their proposed projects and inventions to a panel of seven judges.

A Portable water purification system (First Place Prize)

Team Members: Saeid Zanganeh (ECE), Navid Zanjani (ME)

Nanotechnology has the potential to impact many aspects of food and agricultural systems. A high yield fabrication of a unique morphology of ZnO nanoparticles in the form of a thin film has been conceived which has a big potential for use in the public health and food industry. As the first part of this project, the antibacterial and antimicrobial activities of this thin film in a liquid media has been investigated. The objective of this study is to fabricate a low priced water purification system using this new morphology of zinc oxide to help people who do not have access to a safe and permanent water purification system.

Energy Star Retrofit (Second Place Prize)

Team Members: Nishang Gupta (ME, BUS), Dana Boyer (CEE)

Appliance repair is a dying art since it is cheaper to buy a new appliance than to get an old one repaired. We aim to reinvigorate this dying art by flipping the business model upside down and seek to have a constant stream of repairable appliances coming to repair. Using small appliance retail stores that offer appliance removal services for their customers as our supply chain, we can streamline the entire appliance repair process. With a streamlined repair process that saves on labor time, this model will be able to not only repair broken appliances, but to also retrofit them with energy efficient parts for Energy Star certification, to reduce US energy consumption by 600 million kWh annually.

Clamp and Pivot Sawstop (CAPS) System (Third Place Prize)

Team Members: Stephen Harmon (ME) Sam Masciulli (ME)

The implementation of large windows in commercial building projects is fueling a billion dollar business for industrial glazing companies across the country. Window frames arefabricated in a machine shop. Currently, aluminum frame stock is braced against a rail which runs the length of the table. All the cuts of one length must be completed before the footing is relocated for the next cut. When the stock length is not evenly divisible by the working cut length, there is a large “drop piece” remaining. The CAPS system will eliminate non3scrap drop pieces from the operation and the need for a working stockpile, replacing the time consuming and arduous job of handling drop pieces with the quick and easy lift3and3pivot operation of the CAPS system.

Symbolhound (Third Place Prize)

Team Members: Thomas Fedtmose (BUS), David Crane (CSE)

This project entails a search engine specifically designed for programmers that enable searching for nonValphanumeric characters on web searches.

UConn Formula SAE places in the top group in the International Competition

UConn Formula SAE places in the top group in the International Competition by Timothy Thomas, B.S., ME 2014, UConn SAE Team Leader

After an eighteen hour trek across the country and a days rest thereafter, the  team began the four day Formula SAE Competition at Michigan International Speedway in Brooklyn, Michigan. The Formula SAE® Series competitions challenge teams of university undergraduate and graduate students to conceive, design, fabricate and compete with a small, formula style, competition vehicle. To give teams the maximum design flexibility and the freedom to express their creativity and imagination there are very few restrictions on the overall vehicle design. Teams typically spend eight to twelve months designing, building, testing and preparing their vehicles before a competition. The international competitions themselves give teams the chance to demonstrate and prove both their creation and their engineering skills in comparison to teams from other universities around the world. The University of Connecticut has fielded a vehicle in the largest of these competitions, Formula SAE Michigan,

team began the four day Formula SAE Competition at Michigan International Speedway in Brooklyn, Michigan. The Formula SAE® Series competitions challenge teams of university undergraduate and graduate students to conceive, design, fabricate and compete with a small, formula style, competition vehicle. To give teams the maximum design flexibility and the freedom to express their creativity and imagination there are very few restrictions on the overall vehicle design. Teams typically spend eight to twelve months designing, building, testing and preparing their vehicles before a competition. The international competitions themselves give teams the chance to demonstrate and prove both their creation and their engineering skills in comparison to teams from other universities around the world. The University of Connecticut has fielded a vehicle in the largest of these competitions, Formula SAE Michigan,  located at the Michigan International Speedway since the team began just seven years ago. With over 120 colleges and universities registered, Formula SAE Michigan is the largest of its kind. Over the course of four days, the cars are judged in a series of static and dynamic events including: technical inspection, cost, presentation, and engineering design, solo performance trials, and high performance track endurance. These events are scored to determine how well the car performs. Come close of competition the team executed an incredible performance placing 20th overall

located at the Michigan International Speedway since the team began just seven years ago. With over 120 colleges and universities registered, Formula SAE Michigan is the largest of its kind. Over the course of four days, the cars are judged in a series of static and dynamic events including: technical inspection, cost, presentation, and engineering design, solo performance trials, and high performance track endurance. These events are scored to determine how well the car performs. Come close of competition the team executed an incredible performance placing 20th overall out of the 120 teams in attendance at one of the most competitive events of the year. This milestone places UConn Formula SAE amongst the elite, solidifying that they are a force to be reckoned with. In the midst of teams with decades of experience, a sizable team base, and much larger budgets, UConn Formula SAE is still considered in its youth as building a successful vehicle involves extensive growth in both engineering and team dynamics. With the continuing support of sponsors and the department of mechanical engineering, UConn Formula SAE is working towards even greater success with the refined design and manufacture of the 2014-2015 vehicle already underway.

out of the 120 teams in attendance at one of the most competitive events of the year. This milestone places UConn Formula SAE amongst the elite, solidifying that they are a force to be reckoned with. In the midst of teams with decades of experience, a sizable team base, and much larger budgets, UConn Formula SAE is still considered in its youth as building a successful vehicle involves extensive growth in both engineering and team dynamics. With the continuing support of sponsors and the department of mechanical engineering, UConn Formula SAE is working towards even greater success with the refined design and manufacture of the 2014-2015 vehicle already underway.