Hybrid-Electric Propulsion System For Commercial And Military Aircrafts

Hybrid-Electric Propulsion System For Commercial And Military Aircrafts

Date: September 19, 2025; Time: 2:30 PM Location: PWEB 175

Abstract: Decarbonizing long-haul air travel is essential to climate change mitigation but remains difficult because present alternatives to fossil fuels are constrained by energy density, mass, packaging, infrastructure, manufacturing readiness, and entrenched operating practices. Hybrid-electric propulsion offers a pragmatic near term pathway by pairing high-specific-energy liquid fuels with electric machines and power electronics to cut fuel burn and emissions while enabling novel engine airframe integration. Our discussions examines how the aerospace and defense start-up Marc-Antoni is developing a hybrid-electric propulsion system for single-aisle aircraft and evaluate its commercial viability across performance, weight, safety, certification, maintainability, and cost. The analysis focuses on core technologies, high efficiency generators and motors, propulsion system configurations, energy storage, and outlines a maturation roadmap. Our discussions also assesses defense applications. Confronted by growing threats from unmanned aerial systems and advanced missiles, the U.S. military is increasing its demand for non-kinetic, high-speed effects such as directed-energy weapons. These systems are limited by onboard power generation, power quality, and heat rejection. We will explore hybrid-electric architectures which could be adapted to combat aircrafts to provide higher continuous and pulsed electrical power with improved thermal margins, thereby enabling advanced electronic warfare and directed-energy capabilities.

Biographical Sketch: Ric Duncanson, a serial tech entrepreneur, is the founder of Marc-Antoni, an aerospace & defense start-up developing hybrid electric propulsion systems for civil and military aviation applications. Ric is an expert in technology transfer and the evaluation of intellectual property for commercialization, as evidenced by his acquisition of over 10 patents, ranging from lithium-ion cell components to a novel turbofan design. From 2017 to 2020, Ric was a member of the New York Institute of Technology (NYIT) Entrepreneurship and Technology Innovation Center (ETIC) program where he developed a robotic steering system for high-performance autonomous vehicles, as well as a four-motor full-torque vectoring all-wheel-drive system for high-performance electric race cars. Currently, Marc-Antoni is a member of the University of Connecticut (UConn) Technology Incubator Program (TIP), where the company is developing several research & development projects, including Titanium Niobium Oxide (TNO) lithium-ion cell, partially superconducting machines, and a superconducting turbofan. Although not a formally trained engineer or scientist, Ric considers himself an autodidact, having cultivated profound expertise in the engineering and scientific principles of the various subject matters associated with his innovations.

Protective Nanocoatings from Polyelectrolytes: Flame Retardancy, Gas Barrier, and High Voltage Insulation

Protective Nanocoatings from Polyelectrolytes: Flame Retardancy, Gas Barrier, and High Voltage Insulation

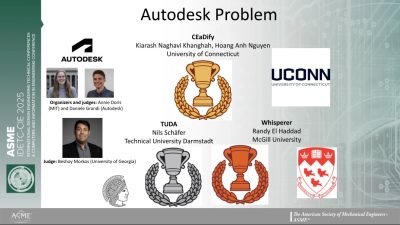

UConn graduate Zihan Wang (’24 PhD) has been honored with the ASME Design Automation Best Dissertation Award for her groundbreaking research in metamaterials. Her dissertation, “Design, Performance Evaluation and Uncertainty Analysis of Metamaterials,” was completed under the guidance of Dr. Hongyi Xu, Associate Professor in the School of Mechanical, Aerospace, and Manufacturing Engineering.

UConn graduate Zihan Wang (’24 PhD) has been honored with the ASME Design Automation Best Dissertation Award for her groundbreaking research in metamaterials. Her dissertation, “Design, Performance Evaluation and Uncertainty Analysis of Metamaterials,” was completed under the guidance of Dr. Hongyi Xu, Associate Professor in the School of Mechanical, Aerospace, and Manufacturing Engineering.