Two ME professors received the 2020 National Science Foundation’s CAREER award, which is the Foundation’s most prestigious award in support of early-career faculty.

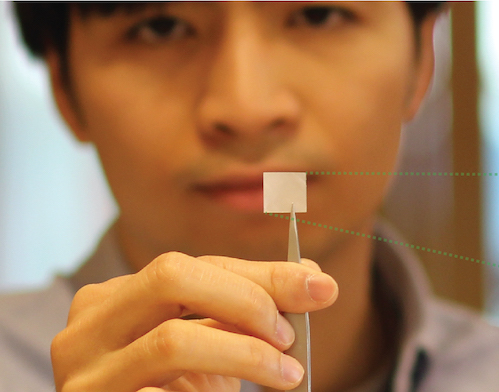

Prof. Xinyu Zhao’s 500k CAREER award focuses on developing a fundamental understanding of flame extinction, which plays a central role in promoting energy security, environmental sustainability, air-travel safety and opportune fire suppression. Droplets, such as fuel sprays in aeronautical combustors and water droplets in pollutant reduction or fire suppression, are ubiquitous in practical combustion systems. When interacting with an established gaseous flame, droplets introduce additional mechanisms to extinguish a flame, through physical processes such as vaporization, dilution, subsequent reactions, modulation of turbulence, and radiative heat transfer. Through this project, Prof. Zhao will investigate the fundamental understanding and develop quantitative descriptions of key factors governing the flame extinction process in presence of droplets.

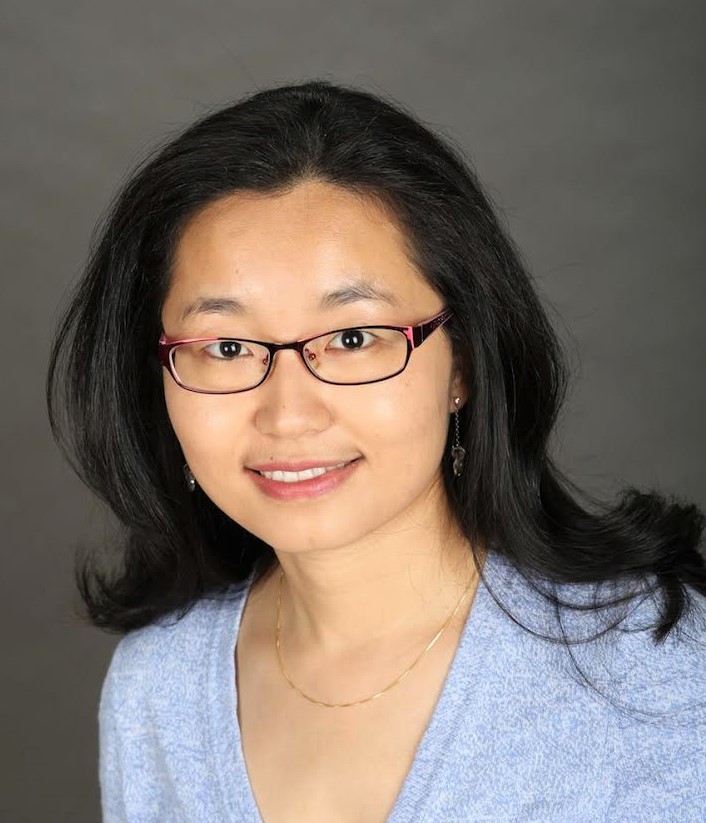

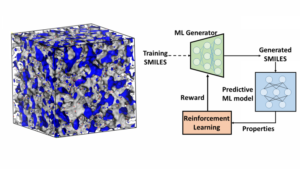

The 592k CAREER award received by Prof. Ying Li will support fundamental research to understand complex mechanical behaviors of thermoplastic elastomers (TPEs). Biodegradable TPEs have the great potential to be used as protective coatings for cell phones, artificial muscles for soft robotics, and polymer electrolytes for batteries. This research project aims to understand and quantify the link between synthesis, microstructure, and mechanical property of TPEs, with the help of multi-scale computational modeling, machine learning, and experimental validation. With tailored mechanical properties, these biodegradable and environment-friendly TPEs can be widely used further to enable an array of novel structural and device applications, alleviating the plastic pollution crisis.