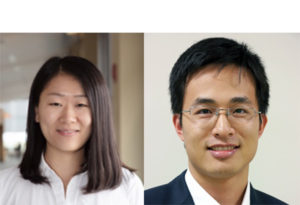

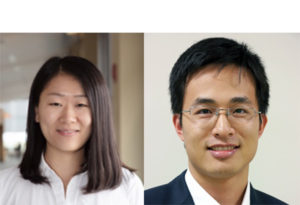

ME graduate student Dan Wang and Professor Xu Chen won the Best Paper (Theory) of the 2018 International Symposium on Flexible Automation (ISFA) for their paper titled “Synthesis and Analysis of Multirate Repetitive Control for Fractional-order Periodic Disturbance Rejection in Powder Bed Fusion.”

ME graduate student Dan Wang and Professor Xu Chen won the Best Paper (Theory) of the 2018 International Symposium on Flexible Automation (ISFA) for their paper titled “Synthesis and Analysis of Multirate Repetitive Control for Fractional-order Periodic Disturbance Rejection in Powder Bed Fusion.”

The ISFA started in 1986 under the co-sponsorship of the American Society of Mechanical Engineers (ASME) and the Institute of Systems, Control and Information Engineers (ISCIE) in Japan. The symposium focuses on automation technologies that are essential to meet the increasing requirements of modern manufacturing and other related fields, such as dynamical systems, robotics, logistics, biomedical systems, and healthcare systems.

The 2018 symposium was held in Kanazawa, Japan from July 15 to July 19. Every year the symposium recognizes two best papers appearing in the Proceedings and presented at the Symposium. One award emphasizes contribution to theory, and the other emphasizes significant or innovative applications/practice. Criteria for selection include the quality of the written and oral presentation, the technical contribution, timeliness, and practicality. Each award consists of a certificate and an honorarium of $1,000.

Wang and Chen’s paper discusses control approaches to advance the quality of repetitive energy deposition in powder bed fusion (PBF) additive manufacturing, pertaining specifically to the repetitive deposition of the laser or electron beam energy. It addresses an intrinsic limitation in control schemes that can leverage the periodicity of task patterns to significantly improve system performance. The long-term impacts will include greater quality assurance of the manufactured parts, new capabilities for large-scale 3D printing of extreme materials, and smarter machines and automation in additive manufacturing processes.