News

Dr. Farhad Imani joins the ME Department

We are happy to welcome Dr. Farhad Imani as a new Assistant Professor in our Department of Mechanical Engineering. Prof. Imani obtained his PhD from Penn State in 2020 and brings to UConn his expertise in advanced manufacturing, and specifically in Industrial Engineering and Operations Research.

His research interests focus on data analytics, machine learning, statistical learning, and decision theory for process monitoring and control, system diagnostics and prognostics, quality and reliability improvement with applications in advanced manufacturing

Prof. Norato joins the Editorial Board of the ASME Journal of Mechanical Design

Dr. Julián Norato, associate professor of Mechanical Engineering, has been named Associate Editor of the ASME Journal of Mechanical Design. This archival journal publishes papers on and embraces broad, interdisciplinary aspects of engineering design research.

Dr. Julián Norato, associate professor of Mechanical Engineering, has been named Associate Editor of the ASME Journal of Mechanical Design. This archival journal publishes papers on and embraces broad, interdisciplinary aspects of engineering design research.

His current research interests lie in incorporating failure, geometric, manufacturing and cost requirements in computational topology and shape optimization techniques for the design exploration of novel and highly efficient structures and architected materials. Dr. Norato is a 2020 Air Force Research Lab Summer Fellow, the recipient of the 2019 ASME Design Automation Young Investigator Award, a 2018 NSF CAREER awardee and a recipient of the 2017 Office of Naval Research Young Investigator Program award. He also serves as Review Editor for the Journal of Structural and Multidisciplinary Optimization.

Prof. Nguyen to Develop Self-Administered Microneedle COVID-19 Vaccine Technology

Prof. Thanh Nguyen has received funding from the U.S. Department of Health and Human Services (Biomedical Advanced Research and Development Authority, or BARDA) to develop a single-use, self-administered microneedle vaccine technology for infectious diseases, including COVID-19.

For more details, read the full story on UConn Today:

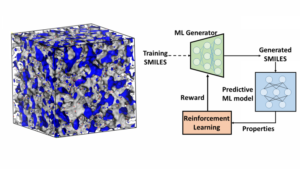

Machine Learning for Thermosetting Polymer Design: Prof. Ying Li’s new AFOSR Young Investigator Award

Prof. Ying Li is in a selected small group of researchers that have received the prestigious Young Investigator Award from the Air Force Office of Scientific Research (AFOSR).

His award will support de novo design of thermosetting polymers with deep reinforcement learning, and will provide new capabilities needed to avoid the traditionally used trial and error approaches and perform rational design to discover novel, yet predictable combinations of properties for cutting-edge thermosetting polymers.

His award will support de novo design of thermosetting polymers with deep reinforcement learning, and will provide new capabilities needed to avoid the traditionally used trial and error approaches and perform rational design to discover novel, yet predictable combinations of properties for cutting-edge thermosetting polymers.

Read the whole story about Prof. Ying Li’s’s Research in UConn Today

Prof. Tarakanova co-organized the First Annual Women in STEM Frontiers in Research Expo (WiSFiRE)

This past January, the University of Connecticut School of Engineering held the Women in STEM Frontiers in Research Expo (WiSFiRE), which brought together and celebrated some of the important research and journeys of female faculty in the School of Engineering. The conference was co-organized by our own Prof. Anna Tarakanova.

Prof. Poludnenko’s Paper on Supernovae Explosions Published in Science

A Senior Design Project Turns into a Patent

https://news.engr.uconn.edu/beyond-senior-design-from-project-to-patent.php

Click on the title to read more.

ME Graduate’s Cancer Treatment Startup Wins $500,000 Grant To Test Their Technology In Space

Click on the title to read more.