http://s.uconn.edu/meseminar4/23/21

Abstract: After billions of years of evolution, it is no surprise that biological materials are treated as an invaluable source of inspiration in the search for new materials. Additionally, developments in computation spurred the fourth paradigm of materials discovery and design using artificial intelligence. Our research aims to advance design and manufacturing processes to create the next generation of high-performance engineering and biological materials by harnessing techniques integrating artificial intelligence, Multiphysics modeling, and multiscale experimental characterization. This work combines computational methods and algorithms to investigate design principles and mechanisms embedded in materials with superior properties, including bioinspired materials. Additionally, we develop and implement deep learning algorithms to detect and resolve problems in current additive manufacturing technologies, allowing for automated quality assessment and the creation of functional and reliable structural materials. These advances will find applications in robotic devices, energy storage technologies, orthopedic implants, among many others. In the future, this algorithmically driven approach will enable materials-by-design of complex architectures, opening up new avenues of research on advanced materials with specific functions and desired properties.

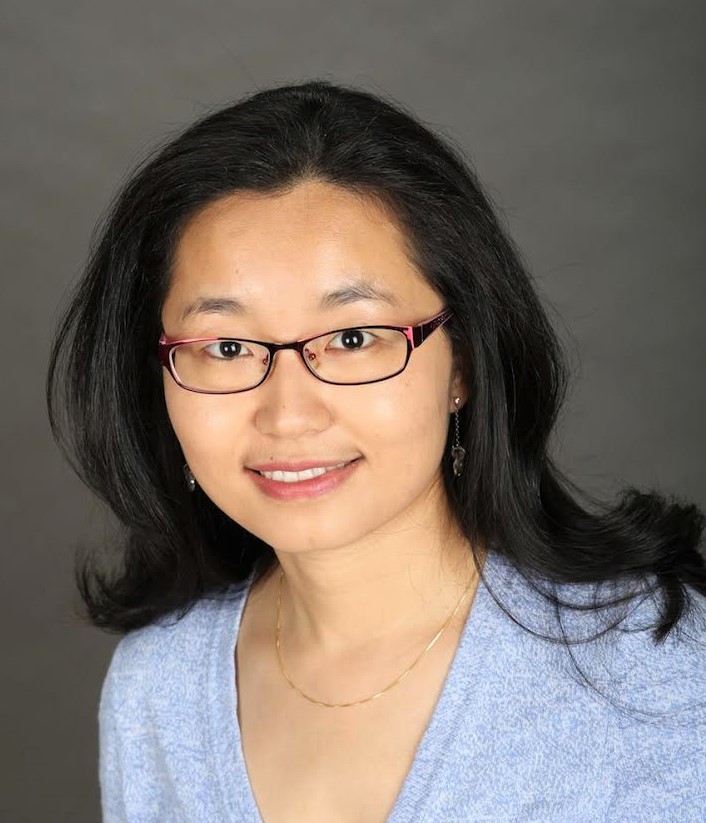

Biographical Sketch: Grace X. Gu is an Assistant Professor of Mechanical Engineering at the University of California, Berkeley. She received her PhD and MS in Mechanical Engineering from the Massachusetts Institute of Technology and her BS in Mechanical Engineering from the University of Michigan, Ann Arbor. Her current research focuses on creating new materials with superior properties for mechanical, biological, and energy applications using multiphysics modeling, artificial intelligence, and high-throughput computing, as well as developing intelligent additive manufacturing technologies to realize complex material designs previously impossible. Gu is the recipient of several awards, including the 3M Non-Tenured Faculty Award, MIT Technology Review 35 Innovators Under 35, Johnson & Johnson Women in STEM2D Scholars Award, Royal Society of Chemistry Materials Horizons Outstanding Paper Prize, and SME Outstanding Young Manufacturing Engineer Award.

Prof. Julian Norato has received a new ARPA-E grant to study Topology Optimization and Additive Manufacturing for Performance Enhancement of High Temperature and High Pressure Heat Exchangers.

Prof. Julian Norato has received a new ARPA-E grant to study Topology Optimization and Additive Manufacturing for Performance Enhancement of High Temperature and High Pressure Heat Exchangers.