Dr. Nguyen received a NIH R21 trailblazer young investigator award for a project entitled “bionic self-stimulated cartilage”, in collaboration with Dr. Cato Laurencin at UConn Health, school of medicine. This highly-interdisciplinary project aims to integrate a new biopolymer, developed in Nguyen Lab, with a chondrocyte tissue graft to create an exciting hybrid artificial cartilage. The PIs hope this bionic cartilage in implantation will be able to adapt to mechanical joint-force for obtaining an optimal cartilage growth and regeneration. Results from this research will have a great impact for an effective treatment of cartilage diseases such as osteoarthritis. The research is a collaborative work between Nguyen lab (UConn Storrs) in materials processing, device fabrication, tissue integration, and in vitro study, and Laurencin Lab (UConn Health) in animal study and in vivo assessment.

Dr. Nguyen received a NIH R21 trailblazer young investigator award for a project entitled “bionic self-stimulated cartilage”, in collaboration with Dr. Cato Laurencin at UConn Health, school of medicine. This highly-interdisciplinary project aims to integrate a new biopolymer, developed in Nguyen Lab, with a chondrocyte tissue graft to create an exciting hybrid artificial cartilage. The PIs hope this bionic cartilage in implantation will be able to adapt to mechanical joint-force for obtaining an optimal cartilage growth and regeneration. Results from this research will have a great impact for an effective treatment of cartilage diseases such as osteoarthritis. The research is a collaborative work between Nguyen lab (UConn Storrs) in materials processing, device fabrication, tissue integration, and in vitro study, and Laurencin Lab (UConn Health) in animal study and in vivo assessment.

News

Emeritus Prof. Lee Langston goes to Italy with the ASME History & Heritage Committee

Professor Emeritus Lee Langston, a member of the ASME History & Heritage Committee, recently traveled to Palermo, Italy, to represent UConn and ASME at the ceremony recognizing the engine collection housed within the University of Palermo’s Museum of Engines and Mechanisms.

From left to right: Giuseppe Genchi, Terry Reynolds, and Lee Langston. Photo by ASME/Wil Haywood.

From left to right: Giuseppe Genchi, Terry Reynolds, and Lee Langston. Photo by ASME/Wil Haywood.

More details can be found on the ASME website.

Since the invention of the wheel, mechanical innovation has critically influenced the development of civilization and industry as well as public welfare, safety and comfort. Through its History and Heritage program, ASME encourages public understanding of mechanical engineering, fosters the preservation of this heritage and helps engineers become more involved in all aspects of history.

Professor Emeritus Lee Langston is actively involved in the committee’s ASME Landmark program. Historic Mechanical Engineering Landmarks are existing artifacts or systems representing a significant mechanical engineering technology. They generally are the oldest extant, last surviving examples typical of a period, or they are machines with some unusual distinction. Over 270 Landmarks have been designated.

Stephany Santos Wins Ford Fellowship

Stephany Santos Wins Ford Fellowship.Stephany Santos, a doctoral candidate in the imLab, and advised by Prof. David Pierce, recently won a prestigious Ford Foundation Fellowship from the National Academies of Sciences, Engineering, and Medicine.

Stephany Santos Wins Ford Fellowship.Stephany Santos, a doctoral candidate in the imLab, and advised by Prof. David Pierce, recently won a prestigious Ford Foundation Fellowship from the National Academies of Sciences, Engineering, and Medicine.

This fellowship recognizes both her research in cartilage mechanics and her work in engineering education, communication, and mentorship. Her work in engineering education includes quantifying the impact of interaction with female undergraduate research assistants on K-12 students during educational outreach activities designed to engage and educate these students on multiscale biomechanics.

For more information see, http://sites.nationalacademies.org/PGA/FordFellowships/PGA_047958.

David Pierce receives the 2017 NSF CAREER award for his work on collagen microcracks.

This is the National Science Foundation’s most prestigious award to support early-career faculty to become role models in integrating outstanding research and educational objectives to advance the mission of their departments.

Osteoarthritis afflicts nearly 20% of the US population; costs over $185.5BN a year (2007); and causes pain, functional limitations, lost earnings and depression – yet we understand neither its cause nor progression. Researchers have extensively characterized microcracks in bone and sub-millimeter-scale fissures in osteoarthritis, but Dr. Pierce’s lab recently discovered that impact usually considered non-injurious in fact causes micrometer-scale cracks in collagen of human cartilage. These microcracks may lead to pre-clinical osteoarthritis, but the extent to which they grow under repetitive loads during normal daily activities is unknown.

Prof. Pierce’s project, titled “Understanding Collagen Microcracks in Soft Tissues Under Normal Body Loads,” proposed to perform fundamental research to understand growth of collagen microcracks in soft tissues by validating novel computer simulations with new experimental data. Understanding and modeling cartilage microcracks will likely lead to new therapies and/or lifestyle modification strategies for osteoarthritis patients. The research will not only investigate the characterization of one of the earliest observable signs of deterioration likely related to osteoarthritis, but also facilitate studies of other tissues and engineering materials.

Prof. Julian Norato awarded the 2017 ONR Young Investigator Award

UConn assistant professor Julian Norato is part of an exclusive group pf 34 scientists nationwide that have been selected to receive The Office of Naval Research Young Investigator Award, which supports early career academic scientists and engineers that “show exceptional promise for doing creative research.”

Prof. Norato’s project, titled “Computational Synthesis of Composable-Material Structures from Manufacturing-Friendly Primitives”, will advance topology optimization methods for the design of structures made with composite materials with consideration for their manufacturing. Topology optimization is a computational technique that determines the optimal distribution of material within a given space to, for example, design the lightest structure that will not mechanically fail under applied loads. Existing topology optimization methods excel at exploring designs made of homogeneous, isotropic materials—that is, materials that have uniform, direction-independent properties throughout the structure. However, there is a substantial need to advance topology optimization techniques that render designs that are made of heterogeneous, anisotropic materials, such as composite materials, and that take into consideration the geometric requirements of existing composite manufacturing processes. By exploring designs that take advantage of the unique properties of composite materials and that can be more readily translated to fabrication, the techniques advanced by this project have the potential to render significant weight savings and improve the mission performance of Naval aircraft and ship structures.

Prof. Norato leads UConn’s Structural Optimization Laboratory where he and his graduate students develop computational state-of-the-art computational approaches to:

- Incorporate realistic failure mode criteria

- Render designs that are cost-effective and/or close-to-fabrication for a given manufacturing process

- Simultaneously consider the design of a structure and a material system

These capabilities will expand the role of computational design of structures and material systems in the early concept design and advance our ability to push the limits of physical performance (including multifunctional systems), lightweight, and cost effectiveness beyond what is possible today.

Prof Jiong Tang honored by the ASME Hartford chapter.

Prof. Jiong Tang is honored with the Distinguished Engineer of the Year Award presented by the ASME Hartford Section during 2017 Annual Engineer’s Night Awards Banquet.

|

Celebrating women’s contributions to aerospace history and technology with Prof. Dianyun Zhang.

On March 11th 2017, Prof. Dianyun Zhang, graduate student Weijia Chen, and senior Mechanical Engineering students Meagan Ferreira and Nomin Munkhbat attended the “Women Take Flight” event hosted by the New England Air Museum located in Windsor Locks, CT. The event featured activities and presentations celebrating women’s contributions to aerospace history and technology.

Dr. Zhang represented UConn’s Mechanical Engineering department at the event to promote engineering to young children by showing new advancements. Specifically, the group demonstrated how composites are manufactured to the young boys and girls (as well as adults) who attended the event. Curious guests were shown that carbon fiber and the glass fiber are flexible and soft. Then they were asked if they could assess the composite panels, and if they believed they were made from those same materials. Guests were then told about the VARTM (vacuum assisted resin transfer molding) process, and exactly how those flexible fibers can become as tough as metal through curing. It was also explained how the composites are replacing airplane parts that generally use metal. (Contributed by Nomin Munkhbat and Meagan Ferreira)

Prof. Xinyu Zhao receives funding from NSF:CISE:CRII to perform large-scale fire simulations.

The project entitled “Efficient Radiative Heat Transfer Modeling in Large-Scale Combustion Systems” will optimize the a legacy radiative heat transfer code from Prof. Zhao’s lab on the Intel Xeon Phi Knights Landing processors. Currently Prof. Zhao is working with a graduate student (Peiyu Zhang) and an undergraduate student (Andrew Caratenuto) on test problems that are representative of the full-scale problems. Significant speedup has already been observed on knights landing using these test problems.

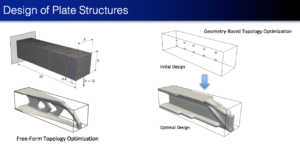

Prof. Julian Norato develops topology optimization with welded plate structures.

Prof. Julian Norato is developing computational techniques for welded plate structures in conjunction with Caterpillar, Inc. These techniques can be a powerful design tool to explore the design of structures from a blank sheet.

Dr. Norato with his student Shanglong Zhang, with funding from Caterpillar, are developing computational techniques for the design of structures made of welded plates, such as those encountered in large structures for heavy machinery and ship structures.

Their work is focused on topology optimization — a computational technique that determines the optimal spatial distribution of material within a space envelope to, for example, design the lightest structure that will not mechanically fail under applied loads. This technique is a powerful engineering design tool to explore the design of structures starting from a blank sheet. Existing topology optimization techniques produce complex, organic designs that cannot be readily fabricated by welding plates. In order to be most economical, this current process in many cases results in the production of large, strong structures typically made of steel. This is the case with the main structures of heavy machinery and ships. Dr. Norato’s topology optimization method renders designs that are made exclusively of constant-thickness plates which can be welded, which greatly facilitates the translation of the topology optimization result to a design concept of the structure that is amenable to fabrication.