Programmable multifunctional materials and structures: Design, realization, and validation

Date: February 27, 2026; Time: 2:30 PM Location: PWEB 175

Abstract: Programmable materials and structures hold great potential for various applications, such as robotics, biomedical devices, and civil structures. The rational design, physical realization, and validation of programmed behaviors in these systems play important roles in enabling functional devices. To encode desired mechanical functionality into structures, we propose a multi-material multi-objective topology optimization approach to inverse design composite structures that achieve complex target mechanical responses under large deformations. The multi-material framework simultaneously optimizes both the geometry, material heterogeneity, and architecture to achieve target behaviors and functionalities. A library of diverse designs is created, showcasing a wide range of precisely programmed nonlinear responses, such as multi-bulking and multi-plateau.

In general, the properties of materials and structures typically remain fixed after being constructed. To enable reprogrammable behaviors, we develop a multi-physics topology optimization approach to discover magneto-active and temperature-active materials that achieve tunable buckling and switchable shape morphing, controlled by magnetic fields and temperature fields, respectively. The obtained systems exhibit one response under one stimulus and switch to a distinct response by applying another stimulus.

To bridge the gap between simulation and fabrication, we explore multi-material manufacturing techniques, introduce advanced path generation methods, and develop direct ink writing (DIW) techniques to fabricate a suite of mechanical, magnetic, and thermal metamaterials and metastructures and experimentally validate their programmed behaviors. The excellent agreement among target, simulation, and experiment demonstrates that the proposed optimization-driven framework, when integrated with hybrid manufacturing techniques, has the potential to systematically design, inform, and create innovative multi-functional materials and structures for various engineering applications.

Biographical Sketch: Dr. Xiaojia Shelly Zhang is a David C. Crawford Faculty Scholar and Associate Professor at the Department of Civil and Environmental Engineering and the Department of Mechanical Science and Engineering at the University of Illinois at Urbana Champaign (UIUC). She directs the MISSION (MuIti-functional Structures and Systems desIgn OptimizatioN) Laboratory. Dr. Zhang holds B.S. and M.S. degrees from UIUC and a Ph.D. degree from Georgia Tech. Her research explores multi-physics topology optimization, inverse design, stochastic learning algorithms, and additive manufacturing to develop multi-functional, sustainable, and resilient materials, structures, and robots for applications at different scales. She is the recipient of the National Science Foundation CAREER Award (2021), the ASME Journal of Applied Mechanics Award (2022), the DARPA Young Faculty Award (2022), the AFOSR Young Investigator Award (2023), the Leonardo da Vinci Award from ASCE (2024), the DARPA Director’s Fellowship (2024), UIUC Campus Distinguished Promotion Award (2025), the Thomas J.R. Hughes Young Investigator Award from ASME (2025), the ASME Henry Hess Early Career Publication Award (2025), the Haftka Young Investigator Award from International Society for Structural and Multidisciplinary Optimization (2025). Dr. Zhang serves on the Executive Committee of the International Society of Structural and Multidisciplinary Optimization (ISSMO) and is a Review Editor for the Journal of Structural and Multidisciplinary Optimization and an Associate Editor for the Journal of Applied Mechanics.

With support from the New York Consortium for Space Technology, UConn and Union College will collaborate to complete a mission for high altitude balloon testing of solid-state actuator used to augment glove functionality for astronauts, as well as a spintronic thermal sensor for space structures. Conducting high altitude balloon testing provides experiential learning to graduate and undergraduate students via full missions, and brings different student majors (e.g. Physics, Chemistry, Computer Science) into the Space engineering ecosystem. Full testing of devices in the Stratosphere will raise the technology readiness level of actuators and sensors, to a TRL 6, enabling collaborations with government and commercial entities focused on Space. Contact Mihai Duduta (mihai.duduta@uconn.edu) if you’re interested in contributing.

With support from the New York Consortium for Space Technology, UConn and Union College will collaborate to complete a mission for high altitude balloon testing of solid-state actuator used to augment glove functionality for astronauts, as well as a spintronic thermal sensor for space structures. Conducting high altitude balloon testing provides experiential learning to graduate and undergraduate students via full missions, and brings different student majors (e.g. Physics, Chemistry, Computer Science) into the Space engineering ecosystem. Full testing of devices in the Stratosphere will raise the technology readiness level of actuators and sensors, to a TRL 6, enabling collaborations with government and commercial entities focused on Space. Contact Mihai Duduta (mihai.duduta@uconn.edu) if you’re interested in contributing.

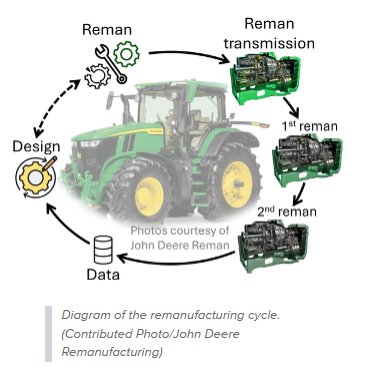

First-year Ph.D. students Mohammad Mundiwala and Aidan Lawlor from UConn’s Reliability Engineering and Informatics Laboratory (REIL) are contributing to the development of sustainable manufacturing solutions through innovative research in product design and remanufacturing.

First-year Ph.D. students Mohammad Mundiwala and Aidan Lawlor from UConn’s Reliability Engineering and Informatics Laboratory (REIL) are contributing to the development of sustainable manufacturing solutions through innovative research in product design and remanufacturing.