Creating Thermal Solutions for Ultrawide Bandgap Electronics

Date: November 7, 2025; Time: 2:30 PM Location: PWEB 175

Abstract: Wide bandgap semiconductors made from GaN and AlGaN alloys have promise for future rf electronics and power switches. One of the key issues that arises in developing future electronics from these materials is the desire for high-power operation, which will place more demands on managing the heat dissipation from these devices. This is especially true when using ternary nitride alloys since they possess an intrinsically low thermal conductivity. This requires careful design of the device architecture and layout to yield effective heat dissipation pathways for wide bandgap semiconductor systems.

In this talk, we will present results on the integration of high thermal conductivity materials with wide bandgap semiconductors as a viable pathway to improve heat dissipation. We will discuss the important role that interfaces play in enabling the integration of materials such CVD diamond, AlN, and SiC while supporting enhanced heat dissipation. We will present results on the use of new interlayers to reduce the thermal boundary conductance between diamond and nitride semiconductors. We will also discuss early results on the development of AlN as a semiconductor with promise for future power device applications. Overall, we will demonstrate the role of modeling in helping to advance the design of thermal solutions for these architectures. Finally, we will discuss the improvements in measurement techniques that allow for the characterization of complex interfaces being developed for advanced nitride rf and power electronics.

Biographical Sketch: Dr. Samuel Graham is the Nariman Farvardin Professor and Dean of Engineering at the University of Maryland. Prior to joining the University of Maryland, he was a professor and chair of the Woodruff School of Mechanical Engineering at the Georgia Institute of Technology. He holds a joint appointment with the National Renewable Energy Laboratory, serves on the Emerging Technologies Technical Advisory Committee for the U.S. Department of Commerce, the Department of Navy S&T Board, and the Advisory Committee for the Engineering Directorate of NSF. His research expertise is in the thermal characterization and reliability of wide bandgap semiconductor technologies and the packaging of organic and flexible electronics.

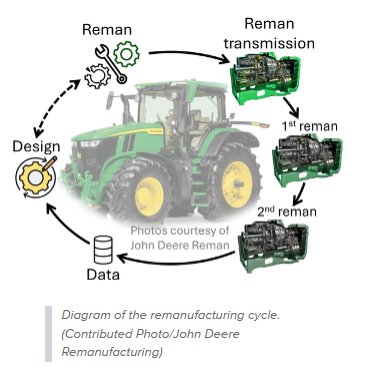

First-year Ph.D. students Mohammad Mundiwala and Aidan Lawlor from UConn’s Reliability Engineering and Informatics Laboratory (REIL) are contributing to the development of sustainable manufacturing solutions through innovative research in product design and remanufacturing.

First-year Ph.D. students Mohammad Mundiwala and Aidan Lawlor from UConn’s Reliability Engineering and Informatics Laboratory (REIL) are contributing to the development of sustainable manufacturing solutions through innovative research in product design and remanufacturing.